DIY Water Pump Carburetor Repair Guide

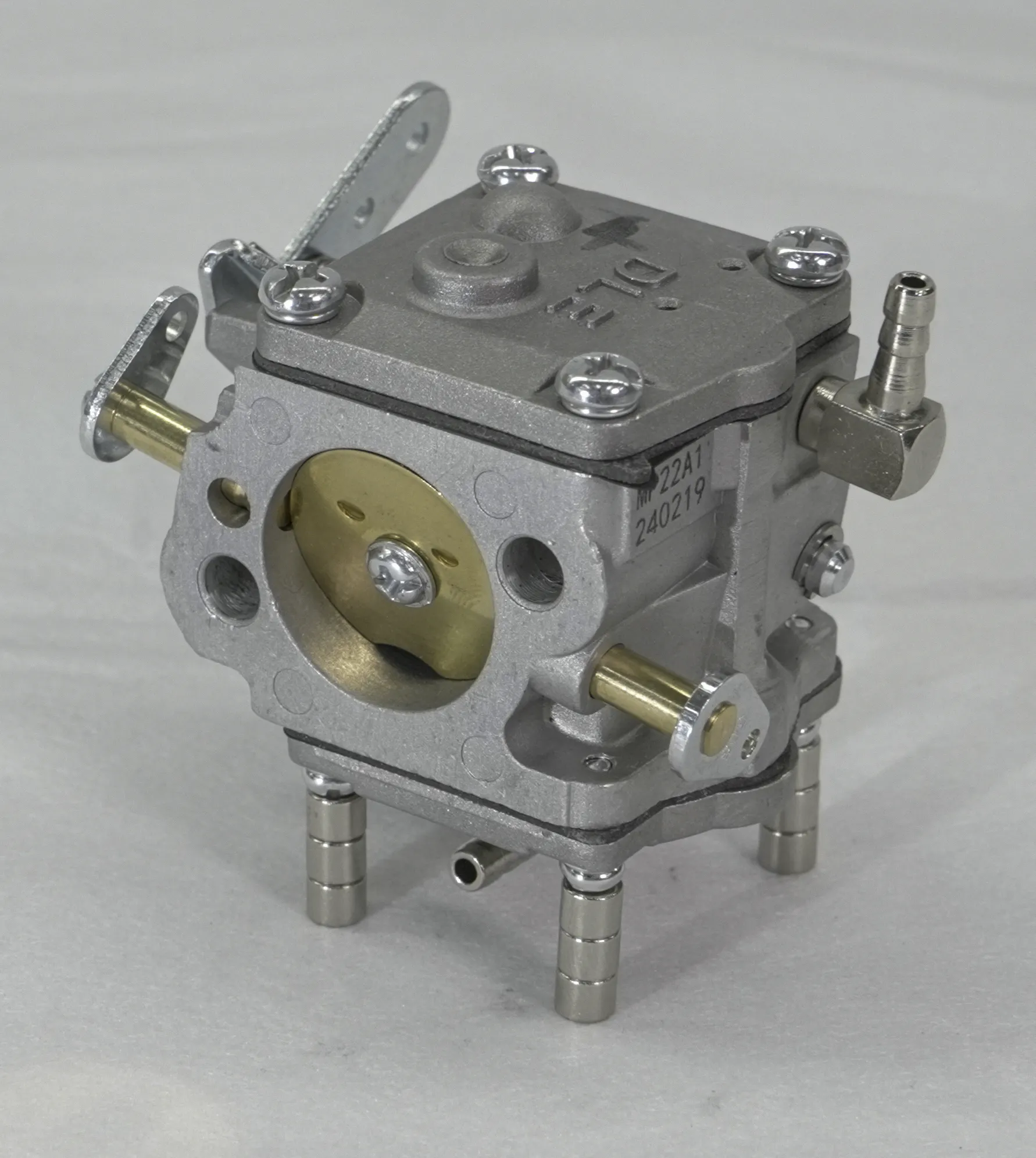

A water pump carburetor is a critical component in engine systems, pivotal for mixing air and fuel to ensure optimal combustion. Found in various applications, including stationary engines, marine, and agricultural machinery, these carburetors play a foundational role in maintaining engine performance and efficiency. Understanding the inner workings and the importance of regular maintenance is crucial for both professionals and DIY enthusiasts.

Regular maintenance and repairs can significantly enhance the longevity and efficiency of the engine. Common issues such as fuel mixture imbalance, improper fuel flow, and air leaks often lead to misfiring engines, rough running, and loss of power. By repairing these issues, you can restore the engine's performance and efficiency, leading to cost savings and better overall engine health.

Tools and Materials Needed for Repair

To effectively repair a water pump carburetor, you will need a comprehensive set of tools and materials. Essential safety gear includes gloves, goggles, and a dust mask to protect against minor injuries and fumes. Tools such as a multimeter, screwdrivers, pliers, and a spray bottle are crucial for cleaning and testing. Common parts to be replaced or adjusted include the fuel cap, air cleaner, and vacuum pump. These items can be purchased from hardware stores like Home Depot or Ace Hardware, ensuring you have everything needed before starting the repair process.

Identifying Common Issues

Diagnosing issues in a water pump carburetor begins with visual inspection and basic tests. Symptoms like misfiring engines, rough running, or loss of power indicate potential problems. Common issues include fuel mixture imbalance, incorrect fuel flow, and air leaks. Visual inspection can reveal blockages, electrode wear, or improper installation. Simple tests, such as checking for leaks or measuring fuel levels, can help identify the root cause of the problem.

Step-by-Step Guide to Repairing Water Pump Carburetors

Disassembling the carburetor involves removing the fuel needle, choke control, and float assembly. Safety is paramount, so wearing PPE and handling tools carefully is essential. After disassembling, inspecting each part for wear or damage is crucial. Adjusting or replacing faulty components, such as the fuel needle or choke control, follows. Cleaning the carburetor with compressed air or a mixture of isopropyl alcohol and water ensures proper function. Reassembling the carburetor requires precision and attention to detail, with the fuel needle adjusted for optimal performance.

Troubleshooting Tips and Advanced Diagnostics

Advanced diagnostics involve using tools like a vacuum pump or OBD-II scanner to address complex issues. Techniques such as flushing the system or checking for blockages can resolve problems. When DIY methods fall short, consulting a professional technician is advisable. Advanced techniques like using a vacuum pump to clear the air filter or checking for electrode wear ensure thorough troubleshooting.

Preventive Maintenance and Regular Inspection

Regular maintenance is key to maintaining optimal engine performance. Inspecting the air cleaner, checking the oil level, and ensuring the vacuum pump functions correctly are essential steps. Suggesting routine oil changes and using airlock tanks to prevent contamination emphasizes the importance of maintenance. Regular inspections can catch potential issues before they escalate, ensuring the engine remains in good condition.

Mastering Water Pump Carburetor Repair

Mastering the art of water pump carburetor repair empowers enthusiasts to restore and maintain their engines effectively. By understanding common issues and following a systematic approach, DIY repair becomes a manageable and rewarding project. Emphasizing preventive maintenance and regular inspections highlights its importance in preserving engine longevity. Encouraging proactive steps and professional assistance when needed, readers can enhance their engine performance and enjoy the satisfaction of a well-maintained system.