DIY Brush Cutter Carburetor Adjustment: A Step-by-Step Guide

Adjusting the carburetor of your brush cutter is crucial for a smooth and efficient operation. Imagine a day of outdoor work, where your brush cutter is your reliable partner. But what if it starts backfiring, idling roughly, or running out of power before you can finish the job? These symptoms can be incredibly frustrating and can even pose safety risks. Proper carburetor adjustment ensures your brush cutter runs like new, saving you time and money.

Improper carburetor adjustment can lead to a variety of issues, such as backfiring, rough idling, and a loss of power. These problems affect not only the performance but also the longevity of your machine. By understanding how to adjust the carburetor yourself, you can keep your brush cutter running efficiently and safely.

Common Issues with Brush Cutter Carburetors

Brush cutters can encounter several carburetor issues. Here are some common signs to watch out for:

- Backfiring: A loud, explosive sound from the carburetor.

- Rough Idling: The engine stutters and stops unexpectedly.

- Loss of Power: Reduced performance during operation.

- Poor Fuel Efficiency: Difficulty starting or running the engine, indicating a faulty carburetor.

These symptoms can significantly impact your brush cutter's performance and safety. Identifying these issues early can help you maintain your machine effectively.

Tools and Safety Gear for Adjusting Your Brush Cutter Carburetor

Adjusting a brush cutter carburetor requires a few essential tools and safety precautions. Heres what youll need:

- Hand Tools: A screwdriver or Allen wrench (to tighten and loosen bolts and screws).

- Maintenance Supplies: Shop rags or carpet (to catch and clean debris).

- Safety Gear: Goggles and safety glasses (to protect your eyes from debris and sparks).

Before you start, ensure the engine is turned off and the brush cutter is disconnected from any fuel source to prevent accidental ignition. Wear sturdy shoes and keep your work area clean and well-organized.

Step-by-Step Guide to Adjusting Your Brush Cutter Carburetor

Adjusting a brush cutter carburetor involves two key steps: adjusting the idle mixture screw and the fuel needle.

1. Accessing the Carburetor:

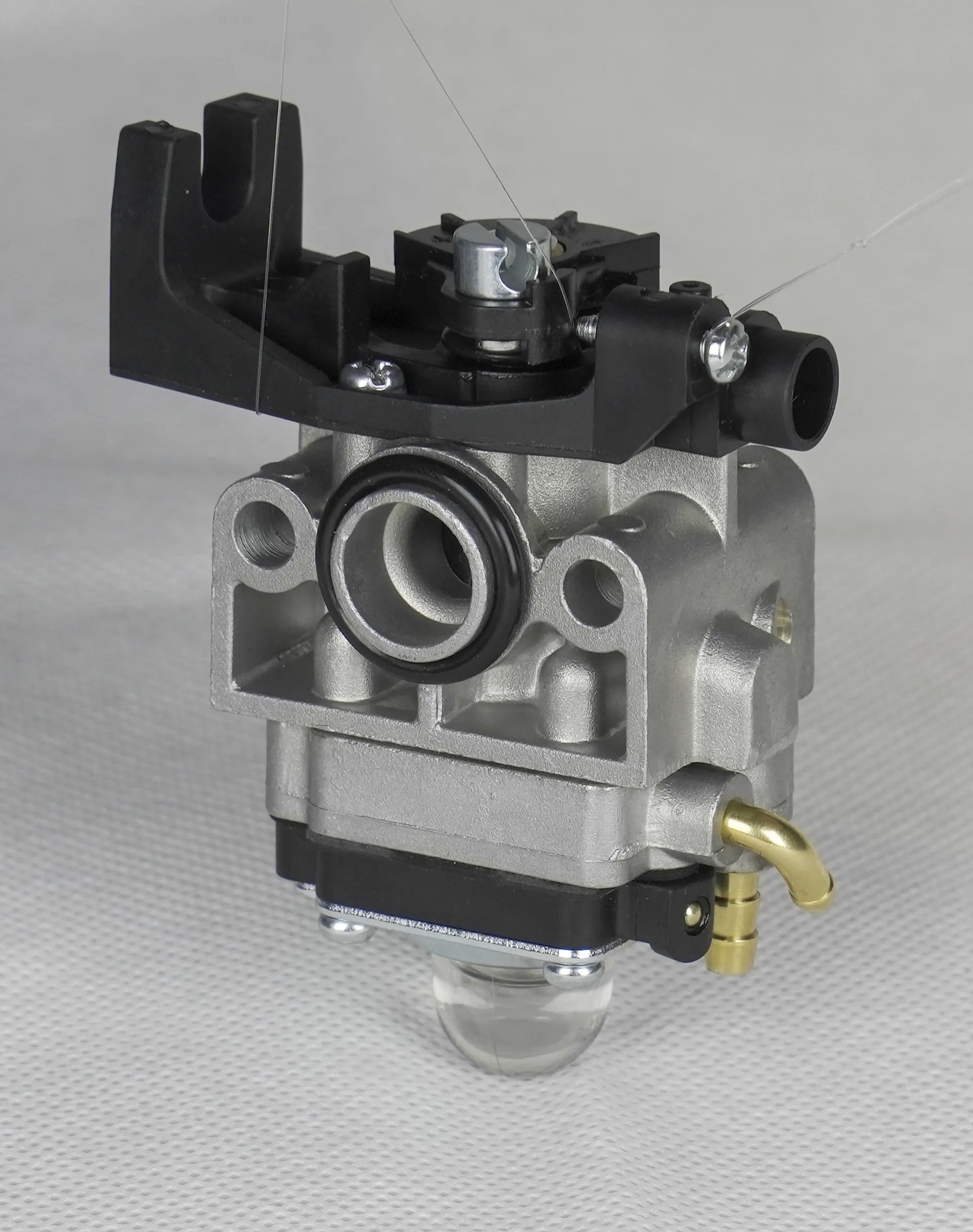

- Locate the carburetor, which is typically found near the engine or on the side of the handle.

- Remove any protective caps or gaskets to access the carburetor.

2. Adjusting the Idle Mixture Screw:

- The idle mixture screw controls the air-fuel ratio during low-speed operation.

- Turn the screw clockwise to increase fuel flow (leaner mixture) or counterclockwise to decrease fuel flow (richer mixture).

3. Adjusting the Fuel Needle:

- The fuel needle regulates fuel flow during high-speed operation.

- Locate the fuel needle seat and adjustment screw. Turn the screw clockwise to raise the needle (leaner mixture) or counterclockwise to lower the needle (richer mixture).

4. Testing Your Adjustments:

- Start the engine and let it idle for a few minutes.

- Listen for any unusual noises or symptoms.

- Fine-tune as needed for optimal performance.

Troubleshooting Common Carburetor Problems

If you encounter problems, start by checking these common issues:

1. Check the Air Filter:

- A clogged or dirty air filter can cause rough idling and backfiring. Clean or replace the air filter.

2. Inspect the Carburetor:

- Look for signs of wear or damage, such as worn gaskets or loose screws. Replace as needed.

3. Check the Fuel Line:

- A clogged or leaking fuel line can lead to lean or rich fuel mixtures. Clean or replace the fuel line.

4. Test the Spark Plug:

- A faulty spark plug can cause misfiring or poor performance. Test the spark plug and replace if necessary.

5. Adjust the Carburetor:

- Make small adjustments to the idle mixture screw and fuel needle as needed to optimize performance.

Comparing DIY Adjustments to Professional Servicing

DIY adjustments can be a cost-effective way to maintain your brush cutter, but they require some skill. Heres a balanced view:

- Pros of DIY Adjustments:

- Cost-effective: Maintain your brush cutter without professional fees.

- Customization: Adjustments can be tailored to your specific needs.

- Time-saving: Adjustments are made without waiting for a professional.

- Cons of DIY Adjustments:

- Knowledge required: Understanding the mechanics is essential.

- Trial and error: Adjusting can be a process of trial and error.

- Tools needed: Basic tools are required, but they must be the right ones.

- When to DIY:

- If you understand the basics and have experience, DIY is a good option.

- If youre an occasional user, DIY can help maintain performance.

- When to Send to a Professional:

- If youre unsure or the issue is persistent, professional servicing is recommended.

- For serious performance issues, a professional can provide a safer and more reliable fix.

Long-Term Maintenance and Tips for Keeping Your Carburetor in Good Condition

To keep your brush cutters carburetor in good condition, follow these maintenance tips:

1. Clean the Carburetor Regularly:

- Remove any debris and clean the carburetor passages to prevent clogs.

- Use shop rags or carpet to catch and clean debris.

2. Inspect the Carburetor Daily:

- Check for signs of wear or damage, and replace or tighten any loose parts.

- Regular inspections can catch issues early.

3. Check the Fuel Filter:

- Replace the fuel filter every few months to ensure clean fuel.

- Clean fuel is vital for optimal performance.

4. Replace the Carburetor Needle Periodically:

- The needle and seat can be worn over time and may need replacement.

- Worn parts can affect the carburetors performance.

5. Keep Your Brush Cutter in Good Condition:

- Store the brush cutter in a dry place and clean it regularly.

- Proper storage prevents moisture damage and keeps your tool in good condition.

By following these tips, you can ensure your brush cutter stays in excellent condition and continues to perform at its best.

Summarizing the Importance of Proper Carburetor Adjustment

Proper carburetor adjustment is key to maintaining your brush cutters performance and longevity. By following this guide, you can adjust and maintain your carburetor with confidence. Remember, while DIY adjustments can be effective, professional servicing is always an option for peace of mind. With these steps, your brush cutter will remain reliable and efficient for many projects to come.

Happy cutting!